MY GOAL WITH THE AEROVAULT®

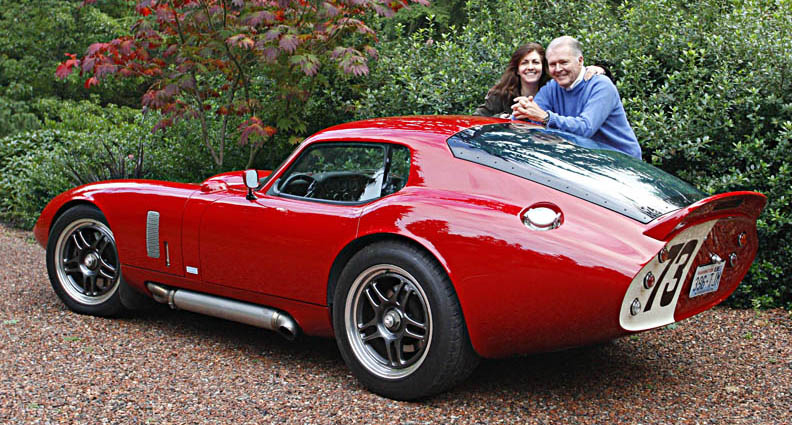

For years I’d looked at various types and sizes of car haulers trying to find something simple and fuel efficient (lightweight with low drag) that handled so well, in all conditions, I could tow it with my daily driver. I wanted something that was easy for one person to load and unload and secure enough to park anywhere overnight. I wasn’t interested in taking my entire shop to the track or creating a “second home” at my destination. I wanted something purposeful and sleek; an aerodynamically efficient, quality built, lightweight sheath for whatever track weapon or show car I wanted to haul.

Over the course of several years I never found it and frustrated by the seeming lack of quality or aerodynamic knowledge in the trailer industry I finally decided to design our own and have it built by a custom fabricator. That was the first Aerovault trailer, the Aerovault MKI.

When traveling with that trailer starting in 2008 I kept hearing constant complaints from other people towing trailers about their tall, heavy, ill-handling, wind-pushing “bread box” trailers. I’d ask, “Why haul all that unusable air in wasted space?” There was no logical answer but everyone seemed to desire the same things I had. Their comments, combined with all the thumbs-ups and shouts of “Where can I get one?” convinced us to make the Aerovault commercially available.

We now build them in our own dedicated facility, here in Henderson, Nevada, using our own custom-built machinery and special fabricating techniques that are unavailable anywhere else. They are built by race-savvy fabricators who take as much pride in their work as I do in mine.

The result is the Aerovault MKII, an aerodynamic and secure, no- compromises trailer, which has now been enhanced even further from our original MKI model.

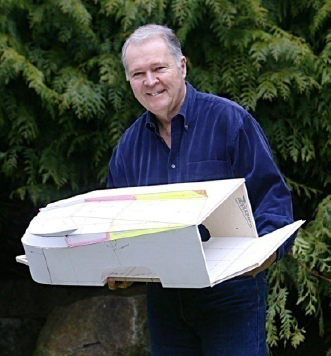

Peter Brock