HOW THEY’RE MADE

The best materials, patented breakthrough semi-monocoque design and ingenious patented construction methods.

The best materials, patented breakthrough semi-monocoque design and ingenious patented construction methods.

Each chassis is built on a custom-made jig table to ensure accuracy and perfection. Note that 3” x 3” beam that runs down the center from the tongue hitch to the rear axle? That’s the money shot. With most trailers that beam is only as long as the tongue. That makes for an unstable trailer, which will also break down quickly. By running the beam all the way back to the rear axle, the load between tow vehicle and trailer is evenly distributed across all the wheels and axles.

So why aren’t other trailers made this way? Cost. There’s more material involved and a LOT more labor to do it the right way. Other manufacturers know you can’t see how they’ve cut this pretty important corner.

Custom Machinery Creates This Masterpiece

Let’s examine the special methods we use to create the main portion of an Aerovault.

The Self-Supporting Sides

What may at first appear to be the most basic part of an Aerovault is actually the most critical and most difficult component to make. The sides of an Aerovault trailer start as 14’ long flat sheets of 1/8” thick 6061 aircraft/marine grade aluminum. An indentation is then “pressed” into the sides to give it strength. This full length channel or “brake” eliminates the need for any internal framing.

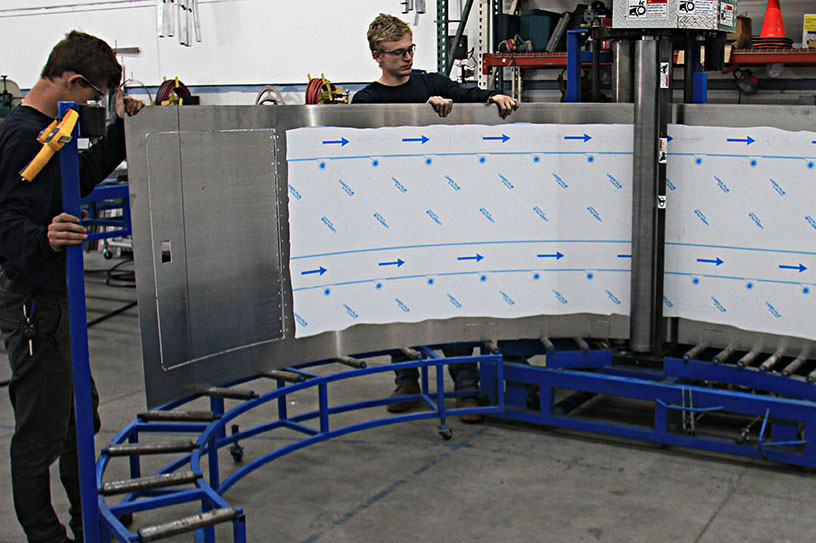

These critical bends are made with Aerovault’s very own 16’ long, 20 ton press brake (nicknamed “Thumper” by our fans). Accurate, smooth, effortless and without scarring, Thumper makes these channels look easy. This Aerovault-built machine is a work of art on its own.

Another custom machine we made curves the 1/8” aluminum sheet for the nose in a way that not only doesn’t weaken the aluminum, it strengthens it. The sheet goes into the roller straight and comes out curved!

The beautiful and functional curved front doors of an Aerovault are laser cut prior to the sheet being rounded. They are an integrally formed part of the rounded nose to ensure a perfect fit.

From the chassis to the tailgate frame, all Aerovault components are fabricated using custom jigs to ensure a perfect fit every time. We even weld the chassis using a dedicated welding table to ensure it is perfectly level.

State-Of-The-Art Composites Provide The Perfect Aerodynamic Shape And Reduce Weight.

Aerodynamic, Lightweight Roof

Always researching improved methods and materials to build the Aerovault’s perfect aerodynamic shape, we explored the use of composites for the most challenging and important aerodynamic aspect of our trailer, the roof. Pleasantly surprised at today’s materials, the Aerovault MKII’s new composite roof is a masterpiece of contemporary materials and great design.

Using boat hull building techniques, the Aerovault’s fiberglass roof is extremely sturdy (think of a boat crashing through waves), yet lightweight, and still provides the characteristics Aerovaults are known for… namely a clean, frameless interior space.

Roof and body are bonded together using state-of-the-art adhesives designed specifically for bonding aluminum and composites (e.g., as used on the Corvette’s aluminum and composite space frames).

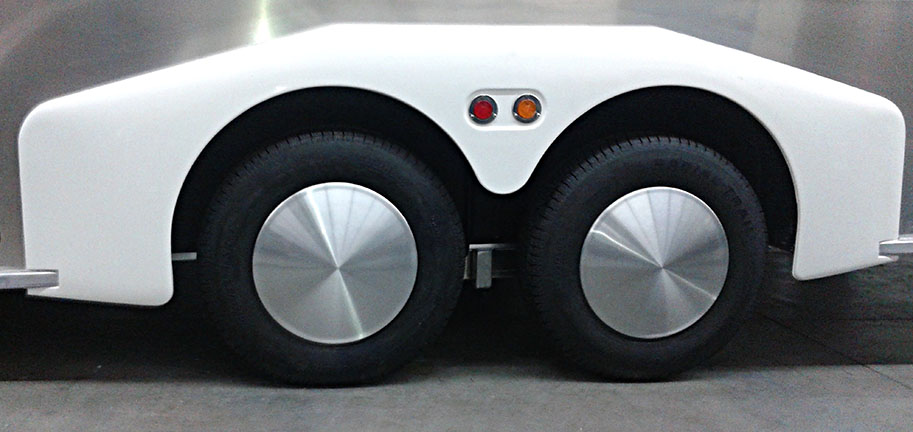

Fenders

With a clean sheet of paper to design the new Aerovault MKII, Brock couldn’t resist adding some flare (literally) to the Aerovault’s side fenders. Made of strong composite materials, inner wheel wells and outer fenders lock in place on each side of the Aerovault’s aluminum sidewalls, adding additional strength and a great look.

Gelcoat

Composite pieces get their color from UV-resistant gelcoat when made, not paint applied later. Their finish is an integral component of each piece and free of maintenance.